Opportunities for Students

In the Kosekgroup we build our results on a combination of theoretical (computer modeling) and the experimental approach. This combination leads to deeper understanding of the scientific challenges and their solving. Students can choose if they like to pursue more to the experimental work, constructing the scientific apparatus or theoretical work. For every work, we have an available consultant, which will spend time with his/her student.

Our main focus is the study of polymers. It begins with the production process, where we optimize real industrial reactors (i.e., lowering of the production costs while preserving the product quality). We investigate the whole polymerization process using modern computational methods. Sub-processes are also studied experimentally by many different methods (TD-NMR, gravimetric sorption balances, video-microscopic apparatus, pressure decay apparatus). We focus also on a more specialized topics such as: flow in 3D printers, foams, charging of polymer particles, sophisticated polymer kinetics and more.

We've started also another individual branch with a focus on the global problem of the energy storage.

Some fields are more discussed below and list of topics (which are not all and can be adapted) is here: Kosekgroup topics for students (in Czech)

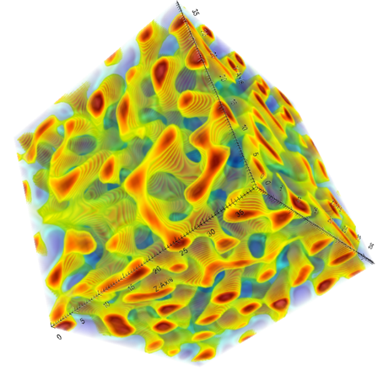

In the chemical engineering, not everything can be easily inspected by the experiments, usually due to the spatial scale, which is on the level of micro- or nanometres. Therefore, computer modeling is sometimes the only acceptable approach. For solving such challenges, students obtain skills in the field of chemical engineering, mathematics and computer science. As concerning the computer science, the student will learn: sophisticated advanced algorithms, modern post-processing methods (results visualization, animation), data analysis, parallel computing on the graphical processing units, working with Linux and more.

Computer modeling is a part of all the following topics.

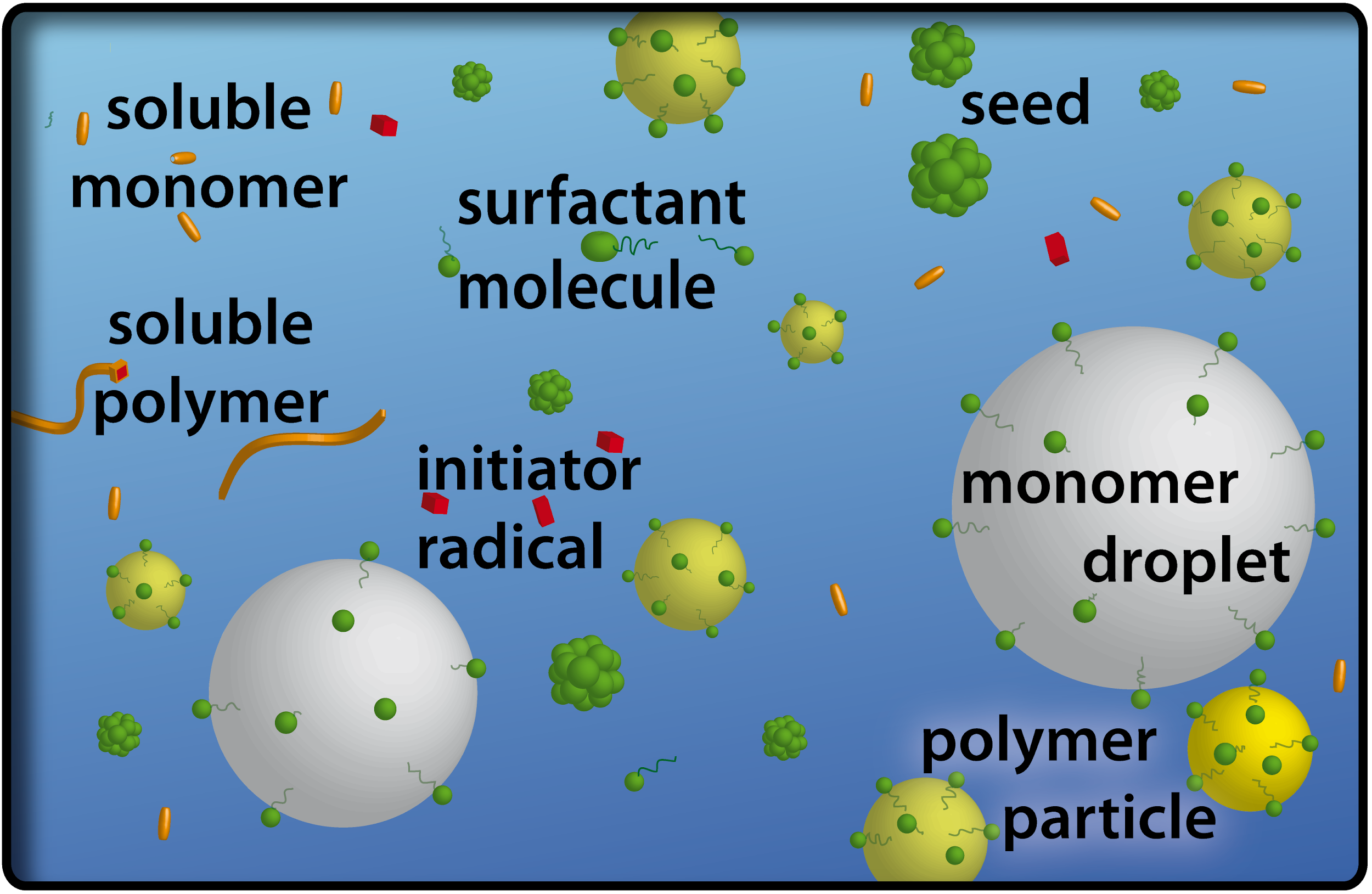

Polymerisation process coupled with computer modelling opens a vast field for optimising material properties and reaction efficiency. Among polymerisation processes, we mainly focus on emulsion polymerisation, which on one hand enables the production of nanoparticles with extraordinary properties, but on the other hand, brings complexity to the system connected with multiple phases present in the emulsion. Our studies and algorithms are tested and implemented on real industrial reactors.

Most modelling outputs need an experimental background for validation or deeper understanding of the physics in the system. Our group experimentally study polymer softening, morphology and other phenomena related to thermodynamics.

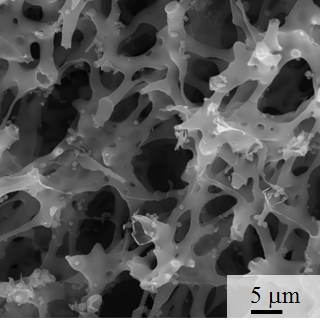

Nano- and micro-cellular polymer foams. Due to their structure, they have many extraordinary properties, e.g., they are excellent thermal and acoustic insulators. Thus, polymer foams are in the forefront of the interest in the construction and other sectors. The formation, structure and resulting material properties of polymer foams are the main part of our research

One of the topics we are focused on is an electrospraying. It is an effective method for nanoparticle creation. In our research group, the electrospraying process is studied from three different points of view. The first one is a basic research of all processes occurring during the electrospray deposition. The possible applications of deposited layers in the area of energy storage (supercapacitors, batteries) or surface treatment (superhydrophobic coating, photocatalytic layers, dyeing) are the second one. All the experiments are done using the self-made device, the construction and development of the device is the third task in this topic.

The Laboratory of Energy Storage is engaged in the research of promising electrochemical energy storage technologies. In particular, research focuses on the study and description of the processes taking place in so-called flow batteries and metal-air cells. Individual factors influencing the efficiency, cost and durability of storages based on these technologies are experimentally and theoretically studied. The main research directions in the area of flow batteries are: study of kinetics of electrode reactions and their catalysis, experimental and mathematical description of transport properties of membranes, optimisation of battery stack geometry with respect to ohmic and hydraulic losses and experimental and mathematical description of losses caused by shunt currents. At the same time, the research group focuses on innovations for metal-fuel cell fuel technology, which can be applied in mobile applications. In recent years, we have started research of new electroactive organic substances, which may mean a revolution in existing technologies for both stationary and mobile energy storage.